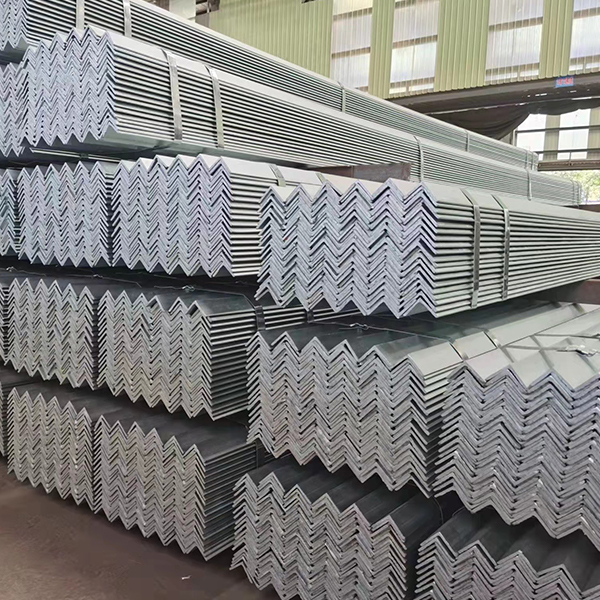

Angle Steel Specifications and Construction Uses Explained

Angle steel, commonly referred to as L-shaped steel, is a fundamental structural component in construction and engineering projects. Its unique 90-degree profile provides exceptional strength and versatility, making it indispensable across various applications. Understanding its specifications and proper usage is crucial for ensuring structural integrity and project success.

Key Specifications of Angle Steel

Angle steel is primarily categorized by its leg dimensions (width) and thickness, typically measured in millimeters (e.g., 50×50×5mm). The two main types include:

Equal Angle Steel: Features legs of identical length (e.g., 40×40×4mm), ideal for symmetrical load-bearing structures.

Unequal Angle Steel: Has legs of differing lengths (e.g., 100×75×6mm), used where asymmetric support is required.

Standard materials range from carbon steel (Q235B, Q355B) for general construction to stainless steel (304, 316) for corrosive environments. Some suppliers also offer galvanized or powder-coated variants to enhance durability in outdoor or industrial settings.

Construction and Engineering Applications

Structural Frameworks: Forms the backbone of building skeletons, roof trusses, and support columns due to its high strength-to-weight ratio.

Bridges & Infrastructure: Reinforces bridge girders, highway barriers, and transmission towers.

Industrial Machinery: Serves as a base for heavy equipment, conveyor systems, and storage racks.

Architectural Detailing: Used in modern façades, staircases, and decorative features.

Proper fabrication techniques, including welding and bolting, are critical to maximize performance. Engineers often specify thicker gauges for high-stress applications, while thinner profiles suffice for non-load-bearing uses.

Comments

Post a Comment