Acetate Tow Properties: Factors Affecting Filter Performance

Using Acetate Tow As A Filter

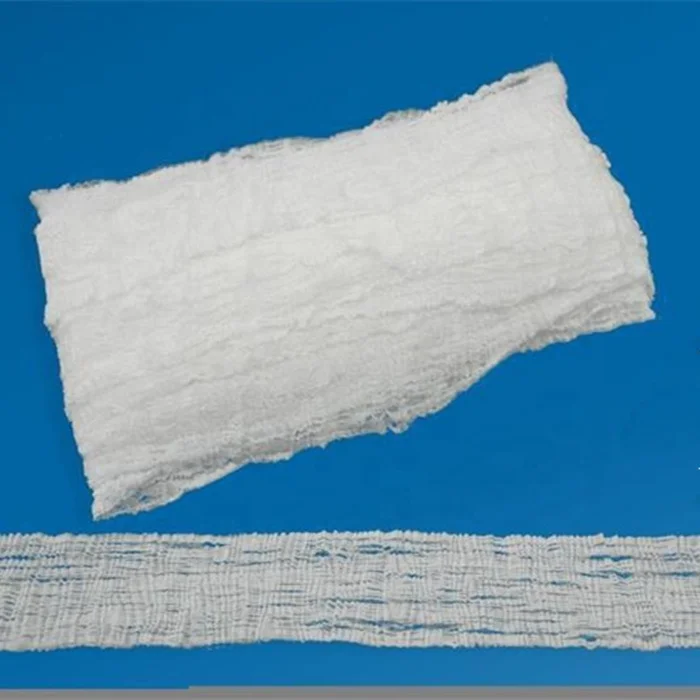

Acetate tow is a unique material utilized in the making of cigarette filters. This is an important role as it helps to filter out the harmful chemicals present in smoke that people inhale from cigarettes. This article explores acetate tow and how it affects filter performance.

The Benefits of Acetate Tow

There are so many benefits to using acetate tow for the production of cigarette filters. For one, it does very well filtering out pollutants from cigarette smoke. It is also cheap, easy to make material and What's more, acetate tow is well considered safe and presents no risks or health hazards to individuals who work with it.

Improvements in Acetate Tow Manufacturing

During the years many changes were achieved in cellulose acetate tow production. These improvements have contributed significantly to the quality of the material, thus increased its efficiency in removing toxic substances from cigarette smoke. There was a standout with advanced technology in the manufacturing space.

Characteristics Which Affect Filter Performance

The performance of acetate tow-based filters depends on a variety of factors. The diameter of the fibers used in manufacturing tow is one important variable There are normally four or six such filters in a cigarette and they interestingly appear to work the more waste particles present, you can almost imagine them as fine mist hanging around which is great for business-gross but good! Fiber density, thickness and the airflow through a filter are other factors that affect their performance.

How To Use Acetate Tow Safely

Acetate tow is on the whole, safe to use although care must be taken due its flammability. Safety guidelines must be assured when using acetate tow in the manufacture of filters and one should use appropriate safety gears to prevent inhaling toxic compounds. The material is also nice and easy to insert into cigarette filters.

Aceate Tow for Quality Standards

If we evaluate the quality and service of acetate tow manufacturers are 3 core elements which need to be taken into account. Choosing a preferred supplier is essential to curb any inconsistencies in acetate tow processing parameters. This is to make sure that the manufactured filters actually work in removing hazardous chemicals from tobacco smoke. They are also need to choose a provider which assists and give support in case of any issues.

Applications of Acetate Tow

Though commonly employed for cigarette filters, acetate tow has various functions in other filtration scenarios such as air filtering. It is highly flexible for various use cases.

In Summary

Then they create cotton filter paper through a filtration process to become the first of multiple layers which are then combined with acetate tow in order since it plays an important role for good quality cigarette. It is important to know the properties of acetate tow and its effect on filter performance in order to create a more effective method for filtering harmful substances out from cigarette smoke. The use of very high standards and safety experiences involved using acetate tow is an important part.

Comments

Post a Comment